Moisture Regain:

Moisture regain is defined as the weight of water in a material expressed as a percentage of the over dry weight of the material or the ratio of water in a material to the oven dry weight of this material is called moisture regain. Moisture regain denotes “R”.

Let,

Oven dry weight of a material =D

Weight of water in this material =W (Original weight-Oven dry weight)

Moisture regain=MR or R

Then,

R%=W/D X 100

Atmospheric Conditions Related To Moisture Regain:

1. Moisture Content:

Moisture content is defined as the weight of water in a material expressed as a percentage of the total weight of the material or The ratio of water in a material to the total weight of the material is called moisture content. Moisture content denotes “C”.

Let,

Oven dry weight of a material =D

Weight of water in this material =W (Original weight-Oven dry weight)

Moisture content=MC or C

Then, C%=W/(W+D) X 100

2. Oven Dry Weight:

The constant weight obtained by drying textiles at specific temperature of 105℃ ± 3℃

3. Humidity:

Humidity is the term used to describe the moisture existing in the atmosphere.

Absolute Humidity:

The weight of water present in a unit volume of a moist air i.e. grains per cubic foot or grains per cubic centimeter. Grain is a measurement of mass. 1 grain= 64.79891 milligrams or 1 grain=1/7000 lb(pound)

Relative Humidity:

Relative humidity is the ratio of the actual vapor pressure to the saturated vapor pressure at the same temperature expressed as a percentage. It denotes RH%.

RH%=(Actual vapor pressure)/(Standard vapor pressure)X 100

Actual Vapor Pressure (ea):

Actual vapor pressure is the amount of water vapor in a volume of air. It denotes ea. It’s a factor in moisture regain.

Standard Vapor Pressure:

Standard vapor pressure refers to the vapor pressure of a substance measured at a standard atmospheric pressure, typically defined as 1 atmosphere (atm). It denotes P.

4. Standard Atmosphere:

Standard atmosphere is defined as an atmosphere at the prevailing barometric pressure with a Relative humidity of 65% & Temperature of 20⁰C (68⁰F)

5. Testing Atmosphere:

Testing atmosphere is defined as the atmosphere with a

Relative humidity →65% ± 2% and

Temperature→ 20⁰C ± 2⁰C(68⁰F ± 4⁰F).

For tropical and subtropical countries a higher standard temperature of 27⁰C ± 2⁰C is use as a standard.

Standard Moisture Regain:

The moisture absorbed by a particular weight sample in standard atmosphere after treating at (105⁰C ± 3⁰C) is called standard moisture regain. It is also called official regain.

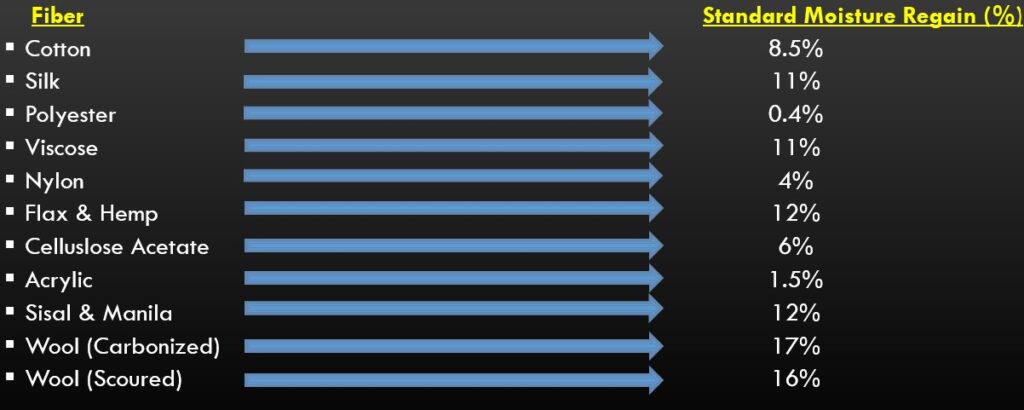

Standard Moisture Regain of Different Textile Fibers:

Correct Invoice Weight (CIW):

The weight obtained after adding standard moisture regain to the oven dry weight is called Correct Invoice Weight or conditional weight.

CIW= Oven dry weight + Standard moisture regain (official allowance)

Mathematical Calculation of Correct Invoice Weight (CIW):

Let,

Correct Invoice Weight= CIW

Oven Dry weight of the Consignment= C

Weight of the Consignment (at the time of the sampling)= W

Oven Dry weight of sample= D

Original weight of sample= S

Then, C/W= D/S

∴ C= D/S × W

We know, CIW= C × ( 1 + MR% )

= C (1 + R/100)

= C (100+R /100)

Mathematical Problem:

The Oven dry weight of 220 gm of cotton yarn is found to be 200 gm. Calculate CIW for 1000 kg consignment of yarn .

Solution:

Let,

Oven Dry weight of Cotton, D= 200 gm

Original weight of Cotton, S= 220 gm

Weight of Consignment, W= 1000 Kg

We Know, C/W=D/S

∴ C= D/S × W

= 200/220 × 1000

= 909.09 Kg

We also Know,

CIW= C × ( 1 + R% )

= C (1 + R/100 )

= 909.09 ((100+8.5)/100) [ As. Cotton M.R. = 8.5%]

= 986.36 Kg.

Mathematical Calculation of Moisture Regain for Blend:

XAB=(PARA+PBRB)/100

Where,

PA= Amount of material A in the blend

PB= Amount of material B in the blend

RA= Moisture Regain of material A

RB= Moisture Regain of material B

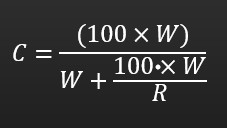

Relation Between Moisture Regain and Moisture Content:

We know,

Moisture regain, R%=W/D X 100……………………………………………(I)

Moisture content, C%=W/(W+D) X 100…………………………………(II)

D= W/R X 100……………………………………………………………………………(III)

From (I), (II), (III) we can get,

Finally,

C=100R/(100+R)

Again for,

R= 100C/(100-C)

Hygrometer:

The instrument used in the determination of the humidity are known as hygrometer or psychrometer.

Different Types of Hygrometer:

For the measurement of atmospheric conditions, there are different types of hygrometer-

- Wet and dry bulb hygrometer

- Hair hygrometer

- Electrolytic hygrometer

1. Wet and dry bulb hygrometer:

Construction:

There are two thermometers, one of them is uncovered which determines the room temperature, is dry bulb thermometer and another bulb is surrounded by a wet sleeve of muslin which determines the lowest /cooling temperature, the muslin sleeve dips into a reservoir of distilled water .

A table of Relative Humidity is kept between the two thermometers from which the percentage of relative humidity is determined by the difference of temperature.

Principle:

- Since wet bulb thermometer is surrounded by a wet sleeve of muslin in an atmosphere which is not saturated, Water evaporates into the air at a rate which is proportional to the difference between the actual humidity and 100% i.e. saturation condition.

- Further since the evaporation is accompanied by cooling the temperature indicated by the thermometer will be less then the room temp.

- By mounting identical thermometer in a frame and arranging one of them to have a wet muslin sleeve over its bulb, two temperature can be read directly.

- The dry bulb and wet bulb difference is noted and tables consulted from which the percentage relative humidity is derived.

Calculation:

Let,

Dry bulb reading =68˚F

Wet bulb reading=61˚F

Difference in reading=7˚F

For difference 7˚ F,

R.H% from table =67%

Uses: It is generally used in mills and industries.

Advantage: The R. H can be determined quickly.

Disadvantage: The results are not sufficiently accurate for purpose of testing because of radiation effect and lack of suitable environment around the instrument.

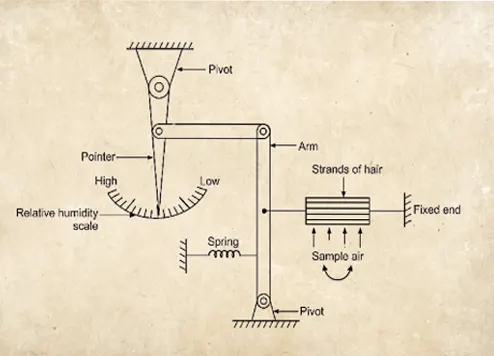

2. Hair Hygrometer:

Human hair has the property of lengthening or shortening as the humidity of the surrounding air increases or decreases. By anchoring a band of hairs to a suitable lever system, the relative humidity may be indicated directly, and if required, recorded on a chart. Great accuracy is not claimed with this type of instrument. For example, to within 3 or 4 percent for the range of humidity 30 to 80 percent and temperature 500C to 700C.

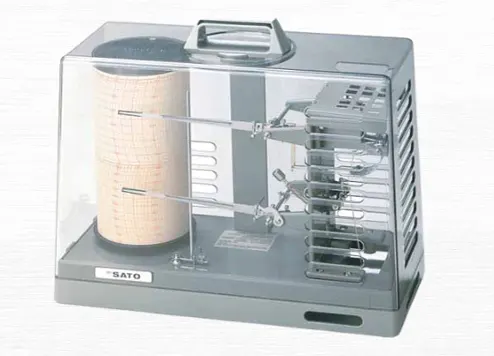

Thermo-Hygrograph:

A combined temperature and humidity recording instrument is called thermo-hygrograph. This uses a bi metallic helical coil for the temperature measurement and a band of human hair for the RH% measurement.

Factors Affecting The Moisture Regain of Textile Material:

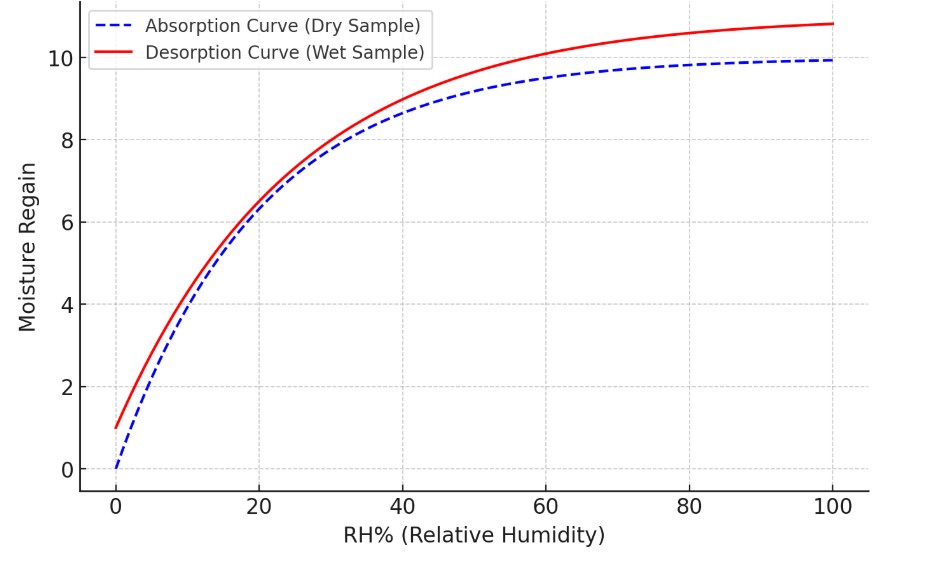

1. Relative Humidity:

It is the main factor which affects the regain of textile fiber. The amount of regain depends upon the moisture present in the atmosphere i.e. if relative humidity is higher , the fiber will absorb more water from the air.

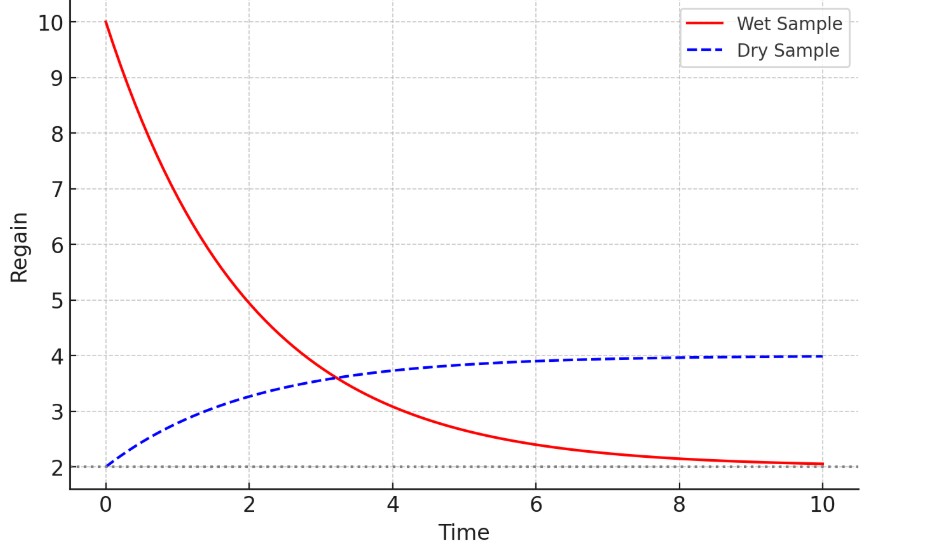

2. Time:

When a material placed in a given atmosphere, it takes a certain amount of time to reach equilibrium. The “rate of conditioning” depends on several factors. Such as-

- Size of the sample.

- Form of the sample.

- External conditions of the material etc.

For testing, not less than one hour required for yarn in hank form and for not less than three hours required for yarn of all other types of package.

3. Temperature:

For practical purpose, the effect of temperature on moisture regain is not important. It is the relative humidity which plays the major role. A change of 100C will give a change in the moisture regain of cotton of about 0.3 percent; but since it is unlikely that the testing room temperature will ever be 100C or 300C. This effect can be ignored.

4. The Previous History of The Sample:

The previous history of the sample can affect the equilibrium of moisture regain. In case of hysteresis effect, the wet sample has a higher regain value than the dry sample in equilibrium. Processing can also change the moisture regain. Removal of oil, wax and other impurities also bring change in moisture regain.

5. Types of Material:

Different fibers have different moisture regain value in a particular relative humidity. Also loose materials have a higher regain value than compact materials.

Some Effects of Moisture Regain On Textile Fiber Properties:

There are 4 key insight properties that can be affected by moisture regain of textile fiber. They are-

- Physical Properties

- Mechanical properties

- Electrical properties

- Thermal properties

1. Physical Properties:

Absorption of moisture is accompanied by changes in the dimension of fibers. Swelling is mostly transversal since the water molecule penetrate between the more or less parallel molecule chains & exert their forces outward.

Swelling = (Swollen dimension-Dry dimension)/(Dry dimension) × 100%

Although the length of the fiber increases due to absorbed moisture, the net result of the absorbed moisture in the fabrics is a decrease in length i.e. shrinkage. Dimension changes in the fabrics as it passes from one atmospheric to another may result in wrinkled appearance.

Example : Suits tailored in one atmosphere and worn in others, especially in climate change where high humidity are found.

Dimensional Changes Due to Absorption of Moisture :

| Fibre | Transverse or area swelling | Axial or longitudinal swelling (%) |

| Cotton | 21 | 1.1 |

| Wool | 25 | 1.2 |

| Viscose | 60 | 4-7 |

| Acetate | 8 | 0.3 |

| Nylon | 3.2 | 1.5 |

| Silk | 19 | 1.3 – 1.7 |

Advantage of swelling is taken in the design of water proofs. A close wear can be used which becomes even closer as the component yarn swell, thus preventing the penetration of water.

2. Mechanical Properties:

The general effect of water molecules in the fiber is to reduce the size of the forces holding the molecular chains together, thereby weakening the fiber.

Important exceptions to this are found when the vegetables fiber such as Cotton & flax are considered, an increase in strength noted. Other mechanical properties affected by regain included extensibility, crease recovery, flexibility & ability to be ‘set’ be finishing process.

3. Electrical Properties:

The electrical resistance of textile materials is very much affected by the Moisture Regain.

The ratio of the resistance at low moisture regain & at high moisture regain can be up to 100000 : 1. The design of moisture meters are based on the measurement of resistance values of textile. Also Shirley electrical Hygrometer uses the resistance principal.

Other electrical properties affected by the amount of moisture in the material are the di-electric characteristics and the susceptibility to static troubles. Di-electric characteristics are considered in the measurement of irregularity of slivers, rovings’ and yarns on capacity type testers.

4. Thermal Properties:

When moisture is absorbed by textile materials heat is generated. This heat is referred as the “heat of absorption”. Suppose the dry weight of the sample is 1 gm & it is then completely wetted. The heat evolved , expressed in calories per gram of dry meters is termed as “heat of wetting”. For Exam, passing from a room at 18oC & 45% RH into an outside atmosphere at 5oC & 95% RH, a man’s woolen jacket weighing 1 Kg will produce 100000 calorie of heat, i.e. as much heats as normal body metabolism will produce in 1 hour.

References:

- Principles of Textile Testing by J E Booth.

- Handbook of Textile Testing and Quality Control by E. B. Grover, Elliot Brown Grover, Dame Scott Hamby.

- Physical Testing of Textiles by B.P. Saville.

To learn more on textile testing and laboratory accreditation you can check on the following article:

- Testing Of Textiles: Why Is It Important For The Textile And Apparel Industries?

- 10 comprehensive steps in textile fiber sampling method

- Fabric Abrasion Resistance: Martindale Abrasion Testing Process

- Fabric Hand feel evaluation by Fabric Touch Tester (FTT)

- Color Fastness test

- Washing fastness test method: ISO 105 C06

- ISO/IEC 17025 Laboratory Accreditation Process

- ISO/IEC 17025 Laboratory Accreditation Advantages

- KEY STEPS FOR CONDUCTING AN EFFECTIVE QMS INTERNAL AUDIT