Synthetic fibers:

Synthetic fibers are produced from the chemical components by chemical synthesis. These fibers are also referred to as chemical fibers or artificial fibers. Some examples of synthetic fibers are nylon, polyester, polyurethane, etc.

Fibers (Polymers/materials) are of 3 (three) types depending on the production styles.

- Originated in the fibers form from nature. i.e. we called natural fibers. They can be used directly to the conversion process without any modification.

- Basic components from nature but must be modified by Process for polymer Production and then fibers production.

- Synthetic fibers, which polymers are produced chemically by chemical synthesis, first polymer production, then filament production.

Classification Of Synthetic Fibers:

- Natural Polymers

- Synthetic polymers

- Others

1. Natural polymers:

- Regenerated cellulose /modified cellulose (viscose Rayon, cuprammonium rayon etc.

- Regenerated protein (casein)

- Cellulose-esters (cellulose-acetate, triacetate)

- Miscellaneous (Alginate, natural rubbers)

2. Synthetic polymers:

- Polyamides.

- Polyesters

- Polyurethane

- Poly olefins

- Synthetic rubbers

- Polyvinyl derivatives-

- poly vinyl chloride (vinyon)

- Poly acrylonitride (Acrylic and mod acrylic)

- Poly vinilidine chloride

- poly tetra fluro ethylene (Teflon)

- Poly vinyl alcohol (PVA)

- Polystyrene (water proof fiber)

Flow diagram for the classification of synthetic fibers:

Synthetic fibers are also classified on the basis of their behavior during heating:

Thermoplastic fibers (Thermoplast): Fibers which are when heated appropriately, the thermoplast melts on fuse and exhibit continuous flow preferably under pressure and most of them can be dissolved in appropriate solvents. e.g. Nylons, vinyl chloride cellulose acetate, acetate rayon etc.

Non thermoplastic fibers (Non theremoplast): most of non thermoplasts begin to decompose on heating before exhibiting plastic-flow and they can be seldom dissolved in solvents. e g. all cellulosic fibers, available in nature together with viscose Rayon, cuprammonium -Rayon (regenerated cellulose), wood, asbestos falls in this category.

The basic operation involved in synthetic fiber Production-

- Reduction of polymeric material to a liquid state by melting or by dissolving in a solvent or in some solubilizing agent.

- Extrusion of liquid (molten/dope solution) under pressures through the fine holes (orifices of spinneret)

- Rapid and continuous solidification of the extruded material/liquid.

Manufacturing process of Synthetic fiber:

1. Manufacturing of the fiber forming polymer:

Characteristics of synthetic fiber forming polymer:

- Flexibility: The polymer must have linear flexible macro- molecules with high degree of symmetry

- Molecular weight: The polymer must have higher molecular weight. The average length of the molecular chain should be in order of 1000 A° or more.

- Configuration – The molecule must have the capacity to adopt and extend configuration and the state of mutual alignment.

- Crystallinity: A Polymer should have at least a high degree of inter molecular cohesive power. This indicates, molecular chains have sufficient no of sites for attraction.

- Orientation: A high degree of orientation of the molecules in the polymer is a pre-requisite for producing good tensile strength.

- Resistance to different chemical.

- Straight chain structure.

- Glass Transition Temperature (Tg) – Should be near to Room Temp.

- Crystalline Melting Point (Tm) – 200o – 300o C is suitable.

- Polymer should be soluble in some solvent from which it can be spun.

- Hygroscopic nature – Should be hydrophobic.

All synthetic fibers are composed of long chain molecules known as polymer which are formed by chemical processing. It is the identical factor for many basic characteristics such as glass transition temperature (Tg) crystalline melting point (Tm), density, dyeing behavior, moisture absorption etc.

Common groups in polymers –

Amide or Peptide groups (-CO-NR-) Benzene ring Ether linkage(-C-O-C-) Ester linkage(-C-O-O-) Hydroxyl group (-OH) Nitrile group (-C-N-)

2. Spinning of synthetic fibers:

The main methods of fiber manufacturing i.e. synthetic fiber spinning process are determined by the Physical and chemical properties of polymers. Depending on this, spinning can be of two types mainly –

- Melt spinning

- Solution spinning

Depending on the solidification process solution spinning can be subdivided into two categories:

- Dry spinning

- Wet spinning

so in general man mode fiber spinning can be of 3 types:

1. Melt Spinning:

The process of spinning by which fiber or filament is produced from melt polymer chips by extruding through spinneret. Spinneret orifices generate the number of filament according to the characteristics. Example- Polyester, Nylon, Polypropylene etc. Industrial fiber production process consists of the following operations:

- Feeding of polymer in the form of chips/melts.

- Melting of chips.

- Homogenization of melt.

- Filtration of molten Polymers.

- Uniform feeding to the spin-block of molten polymer.

- Extrusion of molten polymers into filaments.

- Solidification of extruded materials/filaments in the cooling chamber/chimney.

- Application of spin finish.

- Collection of filament to a suitable package.

Requirement:

- The polymer should not be volatile.

- The polymer should not decompose in the molten state & the melting point of polymer should be 30oC less than its decomposition temperature.

Advantages:

- The process is simple and economical

- Any production rate can be choice by minor changes.

- There are no requirements of solvent/ chemicals for recovery.

- Process is more versatile.

- Properties of finished product can be controlled by suitable manipulation. For example- Socks manufacturing.

Drawbacks:

- Only limited no of polymers can be converted into fibers with melt spinning.

- Structural development is Poor.

- Maximum strength cannot be developed.

- Higher Production rate cause higher waste.

- Accurate temperature Controlling is critical job one for uniform and optimum properties.

Typical melt spinning:

Polymer Melting point

Nylon – 6, 6 264oC

Nylon – 6 220oC

PET 264oC

Polypropylene 167oC

Poly ethylene 125oC

2. Dry spinning:

In dry spinning, polymer dissolved in a volatile solvent is introduced into a heated drying chambers where the solvent is evaporated & solid fiber is obtained. This process may be used for the production of acetate, triacetate, acrylic, mod acrylic, PBI, spandex and vinyon etc. Industrial fiber production process consists of the following operations:

- Dissolution of the polymer to the solvent.

- Mixing and ripening of “the polymer solution.

- Metering of the polymer solution through the extruder.

- Filtration of the solution to remove mechanical impurities and undissolved Polymer particles.

- Extrusion of the solution through the spinneret into a vertical drying chamber at 100-150 kg/cm². (Number of orifices depends on diameter of fiber or count. The diameter of the hole is in between 0.2-0.4 mm)

- Solidification of polymer solution by means of heated inert gas, mostly air.

- Application of spin finish for lubrication and anti-static effect.

- Collection of the filaments.

Advantages:

- It is recommended process for heat sensitive filament.

- High spinning speed can be achieved.

- Lower solvent is required because of high polymer concentration.

- The dry spinning method is relatively flexible one and spinning condition can be modified.

- The process is more suitable for filament yarns.

Disadvantages:

- This process requires solvent and so solvent recovery process.

- There is limitation for spinning speed as solvent is present.

- Additional post spinning process is required for complete solvent recovery.

- Spinneret hole configuration in the spinneret is very much critical for uniform outward mass transfer.

Solvent characteristics for dry spinning process:

- Solvent should not be volatile.

- It should be organic.

- It should have low boiling point.

- It should be comparatively cheap.

- It should have low latent heat of evaporation.

- It should be thermally stabilized.

- It should be non-toxic.

Dry spinning solvent:

Fibre Solvent

I) Cellulose – Acetone + (2-6) % water

II) Triacetate – Methylene chloride (40%) +

Methanol (10%)

III) Poly acrylonitrile – Di-methyl formamide or

Dimethyl acetamide.

IV) Spandex – DMF, DMAC.

V) Modacrylic – Acetone.

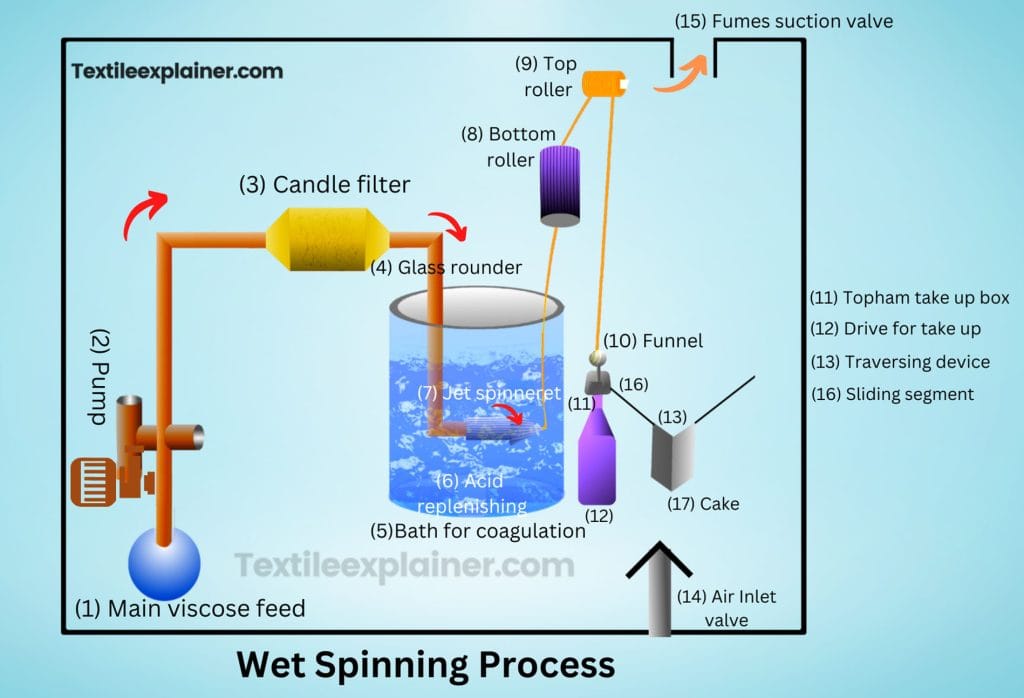

3. Wet spinning:

Wet spinning is the oldest process. It is applied to the polymers which do not melt and dissolve only in non-volatile or thermally unstable solvents. In this process, the polymer is dissolved in a suitable solvent, and the solution is extruded through the spinneret to a liquid bath (Coagulation bath) containing low molecular weight chemicals. Example: Acrylic, rayon, aramid, mod-acrylic and spandex can be produced by this process. Principle of wet spinning process/principle operations involved in wet spinning process:

- Feeding of polymer and solvent.

- Mixing homogeneously in a vessel.

- The solution is transferred to the spin block through the transfer pipe.

- Feeding is controlled by gear pump.

- Filtration of solution to remove impurities

- Extrusion to the coagulating bath.

- Solidification and transfer by means of suitable devices.

Advantages:

- It can be used for any polymer ever for polyethylene polypropylene and nylon can be converted from polymer to their fiber by this technique.

- Fiber can attain maximum theoretical strength.

- The Process can be continuous.

Disadvantages:

- Production rate is low.

- One/more than one bath is required for completely removal of solvent from the polymer.

- Post spinning operations are more lengthy.

- Costly process

- Exact fiber cross section is difficult to control due to inward and outward mass to transfer process.

Wet spinning solvent & coagulant:

Fiber Solvent Coagulant

Viscose Alkaline Water Dill H2SO4 + Na2SO4 + ZnSO4

PVA Water Aqueous NaOH

PAN DMF/DMC + Aqueous DMF/DMC + 40% ZnCl2

60% ZnCl2

Comparison between melt, dry and wet spinning:

| Parameter | Melt spinning | Dry spinning | Wet spinning |

| Heat of spinning | High | Very high | Low |

| Spinneret hole | 2 – many thousands depend on fiber | 300 – 900 | 20000 – 75000 |

| Solvent | Not required | Only volatile organic solvent | Both organic and inorganic solvent can be use. |

| Spinning speed | 2500 – 3000 ft./min | 2500 – 3000 ft./min | 150 – 300 ft./min |

| Productivity | High | Low | High |

| Hazard | Non toxic | Toxic | Toxic |

| Investment cost | Low | High | Low |

| Example | Nylon, PET, Polypropylene | Triacetate, Poly acrylonitrile, Spandex | Viscose, PVA, PAN |

There is a special spinning process termed as Gel spinning.

Gel Spinning: For enhancing strength or other special properties of fiber, gel spinning is specially introduced. In this spinning process, while the polymer is ready for extrusion, it basically not in a true liquid state. They are not completely segregated like a true solution; Their chains are related together related to liquid crystal form. It results in strong inter-chain forces in the processing filaments that can potentially increase the tensile strength of the fibers. Further, the liquid crystals are cling to the fiber axis during extrusion. The processed filaments optimized high degree of orientation relative to each other with strength enhancement. It can also be termed as dry-wet spinning, because first the filaments are passed through air and then acooled further in a liquid bath. Some high strength polyethylene and aramid fibers are produced by gel spinning.

Some special spinning method:

- Reaction or Chemical spinning.

- Dispersed or Emulsion spinning.

- Fibrillated spinning.

Reaction or Chemical spinning:

The fiber forming polymers, those are not compatible with melt, not soluble in suitable solvent or cross – linked in the polymerization process are usually polymerized in this technique. First pre polymer processing, then spun in the reagent bath. Simultaneous process of polymerization and spun happen. For example – Adipic acid reaction with ethylene glycol removes water particles and produce ester. Then polymerization of ester creates polyester.

Advantages:

- Integration with polymerization during spinning.

Disadvantage:

- Not suitable for higher count.

Dispersed or Emulsion spinning.

Polymers which have very high melting point and difficult to solubilized go through this method. Carrier is used in this spinning. PTFH (Poly Tetra fluro hexamine) is produced by this method. The grind polymer is dispersed in water containing a water soluble polymer. Matrix is then spun into filament. When the filament is sintered (heated to near Tm). Polymer particle join together. Then the matrix polymer is removed by dissolving or evaporating.

Fibrillated spinning:

Filament yarn may also be prepared by the extrusion of a thin film which is slit or fibrillated. Fibrillated yarns are formed when a polymer film is passed through a line of rotary knives, usually spaced 2-4 mm apart. A narrow sheet film stretched in longitudinal way to made fibrillated yarns until it is highly oriented and then cracked it into thousands of fine filaments which are called.

Factors of spinning: The spinning process depends on –

- Melting point of fiber. When decomposition temp is higher than melting point of fiber then fiber is spun by melt spinning. When fiber forming polymer is decomposed (components breakdown) at melting point then the dry spinning is used.

- Decomposition temp of fibers.

3. Stretching/ Drawing of synthetic fibers:

Synthetic fiber (filament) produced by melt, wet, dry spinning from the fiber forming polymer cannot be used as textile fibers due to-

- Low tenacity.

- High elongation at break.

- High deformation even at a small load.

- Low modulus

So, it is required to go another operation i.e. drawing/stretching, which converts fibers into textile fibers. Following parameters effect the properties of drawing are-

- Drawing ratio: During drawing the ratio of speed of front (output) roller to the back (input)roller is called draw ratio. Draw ratio=V2/V1. Where V2>V1

- Feed velocity.

- Delivery speed

- Drawing medium.

- Temperature of drawing.

- Stages of drawing.

Drawing includes following changes/modifications to a fiber:

- Length of fiber increases.

- Diameter of the fiber decreases.

- Orientation increases.

- Higher strength, higher modulus and lower extension at break.

- Crystallinity may decrease/increase / constant.

Drawing process:

- Drawing in Un-plasticized condition.

- Drawing in plasticized condition.

- Wet stretching (during wet spinning).

1. Un-plasticized condition:

In cold un-plasticized condition- If the Tg of fiber is about room temperature, then no extra heat is used. At first, un drawn yarn are passed between two control roller and then arranged into snubber pin and stretched through the draw roller.

In hot un plasticized condition-A heater is used between the pin and draw roller and heated at suitable temperature. As for example, for Polyester (Terylene)and Acrylic the draw temperature is 800C

2. Plasticized condition:

In this process, at first the un-drawn yarn is passed through the two pair stretching roller which is taken in a plasticizing bath. Then it is rinsed and wound in a bobbin.

3. Wet stretching:

a) Nascent yarn by wet stretching of controlled Godet:

Direct godet wheel stretching on this process.

B) Snubber controlled wet stretch of nascent yarn:

In this process, at first the nascent yarn arranged with a snubber pin then, stretching is done by godet roller e.g. Viscose rayon is stretched by both above ways.

The skin effect of fiber:

The molecules in the skin of the fiber are more highly oriented than those in the middle. The extra resistance encountered by the spinning solution in contact with the edge of the orifice lines up the long molecules and increases orientation or crystallinity.

Effect of orientation:

- The molecules align them-self parallel or nearly so to the fiber axis.

- Because of the improve alignment, the molecules are able to pack themselves in a more orderly manner so that the fiber becomes more crystalline.

- In some cases, the molecules unfold particularly like Nylon.

- The molecule slide over each other.

- As a result of the improved packing there is more opportunity for inter-atomic attractive forces to be exerted in particular hydrogen bonds.

4. Texturization of synthetic fibers:

A process by which flat surfaces are distorted to have crimps, coils, curls or loops along their length to achieve bulk and greater absorbency.

Basic principle of Texturization in synthetic fibers :

Texturization is performed in 3 steps:

- Plastic condition approach through heating.

- Imparting the required shape of filament.

- Cooling of fiber to retain the shape.

Advantages:

- Resistance to crease.

- Dimensional stability.

- Soft handle and appearance improvement.

- Better perspiration conductivity with higher absorbency.

- Improvement in air permeability.

- Flexibility increases.

Disadvantages:

- Laundering problem.

- Reduction in strength.

- Decrease in abrasion resistance.

- Hairiness formation.

Process of Texturization in synthetic fibers:

- False twist method.

- Stuffer box method.

- Gear box method.

- Knit – de knit method.

- Stress – curled method.

- Knife – edge crimping method.

- Physical/ chemical crimping method.

- Air Jet method.

Some description on synthetic fiber Texturization process:

False Twist method:

Most important and the most widely used technique for producing textured Yarn.

The false twist method combines all three stages –

- Twisting

- Heat setting

- Untwisting in one continuous operation

This method is usually used for manufacturing stretch and modified stretch yarn.

Process:

- The yarn is drawn from the supply package.

- Feed at control tension over the heater and through the false twist spindles.

- Finally wound on a package.

- The twist in the yarn is set when it is between the input feed roll.

- The false twist spindle by heating and cooling before it leaves the false twist spindle.

The productivity depends on spindle speed provided the twist is kept const.

Basically two types of twisting techniques used on false twist texturing machine:

- Twist tube (Spindle)

- Friction twisting.

Example: Nylon, Polyester, Viscose, Acetate and Poly propylene is used.

Air Jet Method:

- Widely used.

- Polyester, Nylon, Air steam is passed over the un-textured yarn.

- For Viscose, only air is passed because water (steam) reduces strength of viscose.

Classification of Textured yarn:

Textured yarn can be classified into three classes:

- Stretch yarn:

Property: High extensible, less bulk.

Texturization process: False twist method, edge crimping.

End use: Socks, swimming costume.

- Modified stretch yarn:

Property: Intermediate between stretch and bulk yarn.

Texturization process: False twist method, edge crimping, heat treatment.

End use: Carpet, Upholstery.

- Bulk yarn:

Property: High bulk, less extensible.

Texturization process: Air Jet, stuffer box, false twist method.

End use: Carpet, Garments.

.

5. Intermingling of synthetic fibers:

The process comprises with the addition or spot welding to protrude filament ends is called intermingling. By this process the synthetic yarn gains smoothness. It is very hard procedure and costly to twist the synthetic fiber.

Ways of intermingling:

- Spot welding: Heat treatment/ Adhesive s are used.

- Air Jet: Composed air at high pressure

Advantages:

- Easy, effective, quick and cheap process.

6. Heat setting:

The process, which induces dimensional stability to fiber, yarns, fabrics or garments with successive heating and cooling in dry and moist conditions is called heat setting.

The different levels of heat setting may be defined as:

- Temporary set.

- Semi-permanent set.

- Permanent set.

Objects:

- To make the yarn, fabric, fiber dimensionally stable.

- To remove shrinkage of fabric.

Disadvantages:

- The fibers become very stiff.

- Uneven shade due to uneven heat set.

- If heat set is done after dyeing, then elimination of dyes as a result of patchiness.

There are some processes, which are required for the betterment of synthetic fiber production. Example: Spin finish, additives etc.

Spin finish:

Spin finishes introduce surface lubricating, plasticizing and static protection to synthetic fiber. Before wind up, spin finishes applied in fluid condition.

Function:

- To lubricate yarn.

- To reduce static electricity.

- To increase the cohesion of the yarn.

- To plasticize the fiber.

Different type of spin finishes:

- Lubricants: Used to control the friction of the fiber. Example: Oils, Poly-glycols, Ester of fatty acid.

- Plasticizers: Plasticizers make the fiber more flexible by reducing the glass transition temp(Tg) and also reduce brittleness. Example: Di-butyl, Silicate esters, Silicate.

- Antistatic agents: Hygroscopic chemicals which can conduct the static charge from fiber to air or earth to improve dielectric constant and to reduce co-efficient of friction. Example- Inorganic salt (such as lithium chloride), Ester of fatty acid (Butyl stearate), Alcohols, amide (NN-dihydroxy ethyl stearamide), Poly oxy-ethylene derivatives etc.

Properties/ Requirements of spin finishes:

- Lubrication for controlling the friction of the filament.

- Must have anti-static property for diminishing of static electricity.

- Cohesiveness property should be provided to the filament.

- Oxidization in the air should not be generated.

- It should induce stable emulsion.

- Spin finishes should not be carcinogenic.

- Wetting property should have good approach.

- Toxicity should not be present.

- Easy availability and cheap.

- Dyeing or finishing process should not be affected.

- Requirement of chemically inert properties.

Additives:

Chemical compounds which are added to fiber forming polymer before polymerization reaction or before spinning to influence the properties of fiber and enhance its performance.

Classification of additives:

1.De-lustering agent:

De-lustering agents are used for the reduction of transparent characteristics, which increase whiteness and reduce yellowness. For the prevention of undesirable luster in the fiber Titanium di-oxide (TiO2) is widely used as de-lustering agent. TiO2 is a white pigment having very fine molecules.

Properties:

- Must be chemically inert and not influenced by wet processing.

- It should be available in fine molecular form with uniform particle size.

- It should be resistant to sunlight.

2. Pigmentation for mass orientation of color:

Color pigments or certain dyes addition to the spinning solution or in the resin polymerization is termed as mass pigmentation. Maximum inorganic pigments are used for the mass orientation of color through pigmentation. Basically for evenness enhance and pigment dyeing mass pigmentation is used.

3. Optical Brightening Agent (OBA):

OBA used for the absorption of invisible ultra violet (UV) radiation and reflect this in the range of visible blue light. It makes the substances to reflect more blue light and makes the material whiter and brighter. Any organic compound comprises with alternate double bond, can be used as OBA.

Properties:

- Colorless dyes.

- Derivatives of Stilbene, Di-benzophenone, Benzimidazole.

4. Light stabilizer: Polyhydroxy benzophenone.

5. Heat stabilizer: Tris (2, 3 di-bromo propyl phosphate) salt of Cu and Mn as phosphate.

6. Special additives: To increase dye take up

7. Solution dyeing: Used in resin polymerization.

8. Whitening: Fluorescent for resist yellowing. Permanent to washing and dry cleaning.