Color fastness:

Color fastness refers to resistance to fading. A dye retains its color on dyed or printed textiles under various conditions like rubbing, light, perspiration, atmospheric gases, or washing. Poor color fastness in textile products often causes significant color variation when exposed to different conditions, such as-

- Type of dye

- The depth of shade

- The quality of the dyeing process

A dye may be reasonably fast to one agent and only moderately fast to another. Dyes can also behave differently when in contact with different agents, for instance dyes which may be fast to dry-cleaning may not be fast to washing in water. Therefore, it is crucial to test any dyed or printed product to ensure the fastness of the colors used in its decoration.

Different agents in color fastness test:

Numerous color fastness tests exist that deal with different agents; the British Standard contains an extensive list of them. Some of the agents that affect colored materials include-

- Light

- Water

- Perspiration

- Ironing

- Bleaching etc.

Different Types of Color Fastness:

- Wash Fastness

- Fastness to rubbing

- Fastness to light

- Fastness to water

- Fastness to sea water

- Perspiration fastness

- Fastness to dry cleaning

- Fastness to bleaching etc.

assessment of color fatness test:

Color Fastness is usually assessed separately with respect to-

1. Color fading:

Color fading refers to the changes in the color of the specimen being tested.

2. Color bleeding:

Staining of undyed material which is in contact with the specimen during the test is bleeding of color.

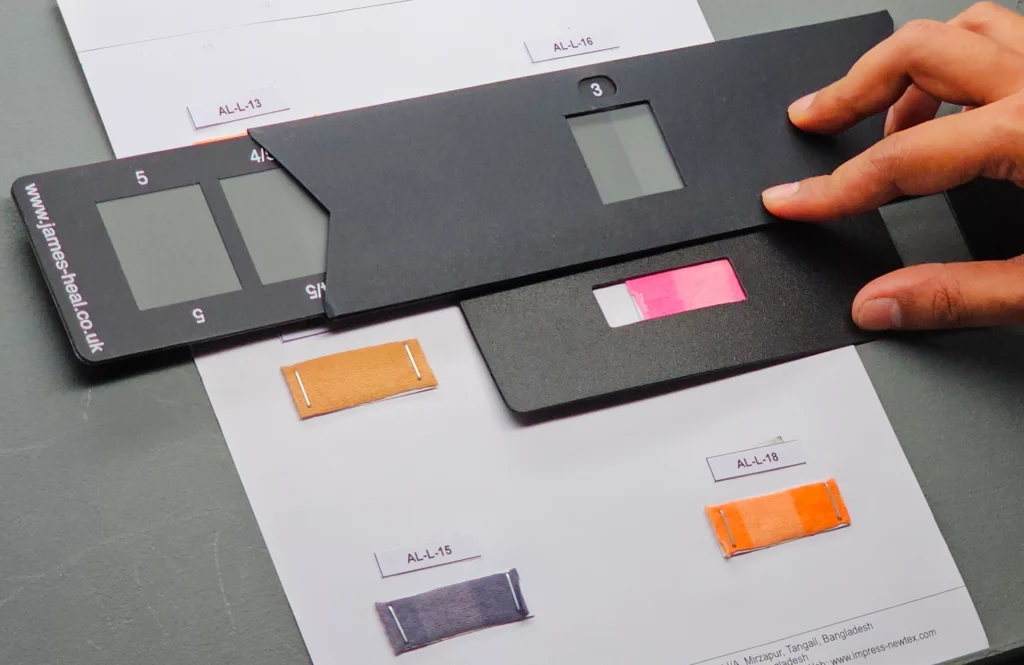

In order to give a more objective result a numerical assessment of each of these effects is made by comparing the changes with two sets of standard grey scale , one for the color change , and the other for staining.

Different types of grey scales:

Different types of grey scales rate the assessment results of color fastness.

1. Color Change Grey Scale:

- Visually comparing the difference in color or contrast between the untreated and treated specimens with the differences represented by the scale.

- The grey scale for color change assesses color fading or changes in color.

- These scales consist of five pairs of grey colored material numbered from 1 to 5.

- Number 5 has two identical greys, number 1 grey scale shows the greatest contrast, and numbers 2,3 and 4 have intermediate contrasts.

- After appropriate treatment the specimen is compared with the original untreated material and any loss in color is graded with reference to the grey scale. When there is no change in the color of a test specimen ,it would be classified as ‘5’, if there is a change, it is then classified with the number of the scale that shows the same contrast as that between the treated and untreated specimen.

2. Staining Grey Scale:

- Visually comparing the difference in color or contrast between the stained and unstained adjacent fabrics with the differences represented by the scale.

- The grey scale for staining assesses color bleeding or staining.

- Staining is measured using a distinct set of grey scales. A rating of 5 indicates no staining with two identical white samples, while a rating of 1 shows one white and one grey sample.

- The other numbers show geometrical steps of contrast between white and a series of greys.

- A piece of untreated, unstained , undyed cloth is compared with the treated sample that has been in contact with the test specimen during that staining test and a numerical assessment of staining is given. A rating of 5 means that there is no difference between the treated and untreated material. If the result is in between any two of the contrasts on the scale, a rating of, for example, 3-4 is given.

Testing Standards for color fastness test:

There are many different testing standards for color fastness testing of fabrics. The key standard settlers for textile color fastness are the Society of Dyers and Colorists(SDC) and the American Association of Textile Chemists and Colorists(AATCC). These two associations have spent many years developing standards and provide excellent information and the advice on their websites.

Other standard test setters in this area are the International Organization for Standardization (ISO) and the International Wool Textile Organization (WTO). These organizations provide standards to cover all facets of textile processing. Their color standards are quite often based on the SDC or AATCC equivalent.

There are some country-based standard organizations, such as the British Standard(BS), American Standard Test Method (ASTM) and Australian Standard (AS).These are generally based on the ISO, SDC or AATCC test method with slight changes made to account for cultural or environmental differences.

For example, it is not suitable to light darkness test fabrics for an Australian market under European natural daylight as the incident angle and intensity are different.

Some Crucial Textile Testing Standards :

Testing fabrics for color fastness test:

Adjacent Fabrics:

Cross-staining of a third-party fabric is assessed using an adjacent fabric fixed to the fabric test sample. Adjacent fabrics come in many types and many forms, including single-component woven fabrics and multifiber woven fabrics.

Single Component Adjacent Fabrics:

The single-component adjacent fabrics commonly used are cotton, wool, polyamide, acrylic, viscose rayon, polypropylene and polyester. It should be plain weave, medium mass per unit area and free from dyes or fluorescent whitening agents. Test involving single-component adjacent fabrics have the adjacent fabric fixed to one or both sides of the fabric test sample. Sometimes a different adjacent fabric composition is used for each side to show staining on two fabric types. Nylon 6.6 is commonly used in staining tests as it tends to scavenge any free dyestuff from the wash liquor better than any other fabric composition.

Generally two single fiber adjacent fabric is attached to specimen. The first of fabric shall be of the same kind of fiber as the material under test and the second shall be that indicated or as otherwise stated.

| In case of first piece | In case of second piece |

| Cotton | Wool |

| Wool | Cotton |

| Silk | Cotton |

| Linen | Cotton |

| Viscose | Wool |

| Acetate | Viscose |

| Polyamide | Wool or Viscose |

| Polyester | Wool or Cotton |

| Acrylic | Wool or Cotton |

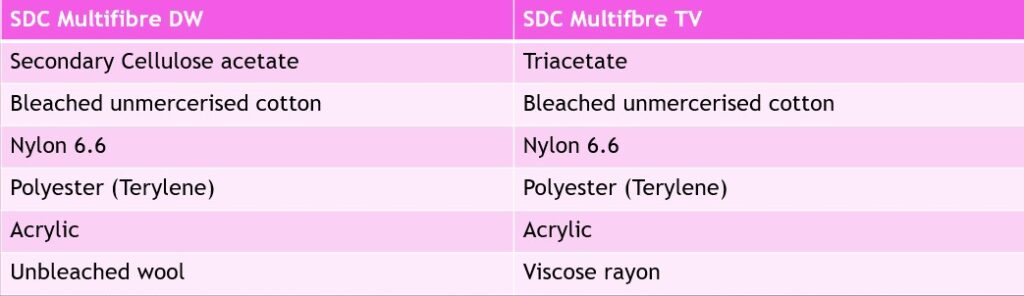

Multi-Component Or Multifiber Adjacent Fabrics:

Multifiber adjacent fabrics allow staining exposure to a range of different fabric types during one test. It is made of yarns of various generic kinds of fibers, each of which forms a strip of specified width providing even thickness of the fabric. The most common supplier of multifiber fabric is the Society of Dyers and Colorists (SDC). The SDC produces two multifiber fabrics: one contains wool and one does not in the following table-

References:

- Principles of Textile Testing by J E Booth.

- Handbook of Textile Testing and Quality Control by E. B. Grover, Elliot Brown Grover, Dame Scott Hamby.

- Society of Dyers and Colorists(SDC)

- American Association of Textile Chemists and Colorists(AATCC)

To learn more on Laboratory testing and accreditation you can check on the following article:

- Testing Of Textiles: Why Is It Important For The Textile And Apparel Industries?

- Fabric Abrasion Resistance: Martindale Abrasion Testing Process

- Fabric Hand feel evaluation by Fabric Touch Tester (FTT)

- ISO/IEC 17025 Laboratory Accreditation Process

- ISO/IEC 17025 Laboratory Accreditation Advantages

- KEY STEPS FOR CONDUCTING AN EFFECTIVE QMS INTERNAL AUDIT

9 thoughts on “Color Fastness test”

❤️

good topic, sir❤️

Thank you sir. Great writing ♥️♥️

Thanks Rahul.

Important topics

Thanks Hasnain.

I like this weblog very much, Its a rattling nice billet to read

and receive information.Raise your business

Very important topics Sir

Thanks for providing

Thanks for the nice words.