A loom is a machine that helps produce woven fabric by interlocking the warp and weft yarns together. It is the primary device used in weaving. Various types of looms are available, which help in weaving various fabrics. The machine’s setting can produce different types of designed fabrics.

Introduction of weaving loom

A weaving loom is a machine that helps in weaving fabric. It is a frame that holds the threads in place while the weaver creates the fabric. There are two kinds of looms: handlooms and powerlooms.Handlooms are the older type of loom and operate by hand. Powerlooms are the newer type of loom and operate by electricity.

Weaving does by interlacing two sets of threads at right angles. The set of threads that run lengthwise is called the warp, and the set of threads that run crosswise is called the weft. The warp threads will hold on to the loom by a warped beam while the weft threads are passed through the warp threads by the shuttle. The weaver can create different patterns by using different techniques.

Weaving is associate degree ancient craft that has been around for thousands of years. It can believe in having originated in the Middle East and spread to other parts of the world. In the past, weaving was done by hand using simple looms. Modern looms have made it possible to weave fabric much faster and more efficiently.

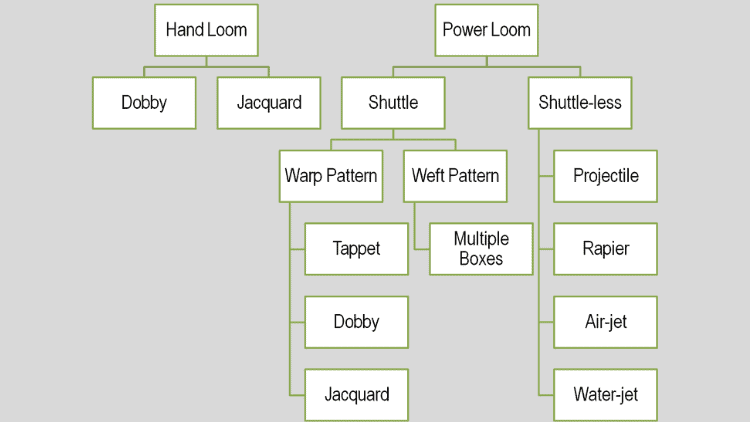

Classification of weaving loom

There are 2 sorts of looms: handlooms and looms. are hand looms and power looms.

- Handlooms are smaller and more portable, making them ideal for use at home or in small workshops.

- Power looms are larger and more expensive, making them better suited for large factories.

Both looms can weave various fabrics, from light cotton to heavy wool. The woven fabric type will determine the size and type of loom needed. For example, a heavy wool fabric will require a larger and more robust loom than a light cotton fabric.

Weaving looms can be classified according to their method of operation. Some looms operate manually, while a machine operates others. Manually operated looms are typically smaller and less expensive, making them more suitable for hobbyists and small businesses. Machine-operated looms are typically more extensive and expensive, making them better suited for large factories.

revelation of weaving loom

The weaving loom has been around for centuries, and its evolution has been fascinating to watch. The earliest looms were simple tools to help people weave fabric by hand. These looms were often made out of wood and were very basic in design.

As time went on, the loom began to evolve and become more sophisticated. The first significant change was the introduction of the treadle loom. This loom allowed weavers to use their hands and feet to operate the loom, making the process much faster and easier.

The following significant change came with the invention of the power loom. This loom was much faster and more efficient than the treadle loom, quickly becoming the standard for commercial weaving. Today, the power loom is still the most commonly used type, but computerized looms are also use for more intricate weaving projects.

Different types of weaving loom

From the image below, you can easily understand an explanation of weaving from the very beginning. From this picture, you can easily understand how one loom came after another and how one loom is related to another. Continue reading the article to know more about these looms.

Hand Loom

Edmund Cartwright built and patented a power loom in 1785, adopted by England’s nascent cotton industry. The silk loom made by Jacques Vaucanson in 1745 operated on the same principles but developed further.

- Dobby

Dobby looms first appeared around 1843, roughly 40 years after Joseph Marie Jacquard invented the Jacquard device that can be mounted atop a loom to lift individual heddles and warp threads.

Dobby is a shedding device attached to a loom to increase design capacity. The dobby controls typically 12 to 24 hold shafts. The dobbies classify as negative or positive, single lift, double lift, crank driven, cam driven, etc.

- Jacquard

The Jacquard mechanism, invented by Frenchman Joseph Marie Jacquard and first demonstrated in 1801, simplified how complex textiles such as damask. The figurine capacity of the jacquard is 1800+. It means it can produce designs with more than 1800 warp threads by controlling them individually, far beyond the capacity of a dobby or tappet loom.

Power Loom

A power loom could be a mechanized loom and was one amongst the key developments within the industrialisation of weaving throughout the first technological revolution. The first power loom was designed in 1786 by edmund Cartwright and was the first built that same year.

Shuttle

These looms ar thought of obsolete in trendy industrial material producing as a result of they will solely reach a most of three hundred picks per minute.

- Tappet

A tappet is a shedding tool placed on the peak of a loom to produce a pattern by using a limited number of heads. The tappet shedding is the combination of tappets and cams motion, which is why shafts lift to form the shed. This type of shed is formed in a tappet loom and is called tappet shedding.

- Dobby

A dobby loom could be a style of floor loom that controls the complete warp threads employing a dobby head. Dobby could be a corruption of “draw boy,” that refers to the weaver’s helpers World Health Organization wont to management the warp thread by propulsion on draw threads.

- Jacquard

The Jacquard loom is a piece of machinery that was made by Joseph Marie Jacquard in 1801. It makes it easier to make fabrics with patterns like brocade, damask, and matelassé. The loom is controlled by cards with holes punched in them. Each hole corresponds to one design row. Each card has several rows of holes punched in it, and the many cards that make up the design are strung together in the right order. It is based on earlier ideas by Frenchmen Basile Bouchon (1725), Jean Baptiste Falcon (1728), and Jacques Vaucanson (1740). It’s wrong to call it a loom. A Jacquard head could be attached to either a power loom or a handloom. During shedding, the head would control the raised warp thread. During picking, what could use more than one shuttle to change the color of the weft? In the 1800s and 1900s, punch card computers were used. The Jacquard loom came before them.

Shuttle-Less

- Projectile

Projectile looms utilize an object propelled across the shed, usually by spring power, and guided across the width of the cloth by a series of reeds. The projectile is then removed from the weft fiber and returned to the opposite side of the machine so it can reuse it. Multiple projectiles are in use to increase the pick speed. These machines can go as fast as 1,050 ppm at their fastest.

- Rapier

This type of weaving is very versatile in that rapier looms can weave using many threads. There are several types of swords, but they all use a hook system attached to a rod or metal band to pass the pick across the shed. These machines regularly reach 700 picks per minute in regular production.

- Air-jet

An air-jet loom uses short quick bursts of compressed air to propel the weft through the shed to complete the weave. Air jets are the fastest traditional method of weaving in modern manufacturing, and they can achieve up to 1,500 picks per minute. However, the amount of compressed air required to run these looms and the complexity of how air jet position makes them more costly than other looms.

- Water-Jet

Water-jet looms use the same principle as air-jet looms but uses pressurized water to propel the weft. The benefit of this type of weaving is that it costs less to use water power in places where water is already there. As many as 1,000 picks can be made in one minute.

Conclusion

So, you have read a comprehensive article on weaving loom. There are different weaving looms, like the ground loom, apron loom, etc. The looms classify based on the frames and their manner of working. The looms operate by a weaver, who is also called a cloth maker. They are the person who weaves the cloth on the loom. They are also called a weaver. So, now it is your turn to share this article on social media.