Yarn Count:

Count is a numerical expression of a yarn, which defines fineness & coarseness. A definition of yarn count is given by the textile institute-” Count, a number indicating the mass per unit length or length per unit mass of a yarn.”

Yarn Count Can Be Expressed In Two Ways :

- Direct System

- Indirect System

1. Yarn Count Measurement In Direct System:

In a direct yarn counting system, the yarn number or count is the weight of a unit length of a yarn.

Let,

N = The yarn number (Count)

W = The weight of the sample at the official regain in the units of the system.

L = The length of the sample

l = The unit of the length of the system.

Then,

N = (W × l)/L

Example: Tex, Militex, Kilotex, Denier, Jute( lbs/spyndle) etc.

2. Yarn Count Measurement In Indirect System:

In an indirect system, the yarn number or count is the number of “ units of length” per “ unit of weight”.

Let,

N = The yarn number (Count)

W = The weight of the sample at the official regain in the units of the system.

w = The unit of weight of the system

L = The length of the sample

l = The unit of length of the system

Then,

N = (L ×w)/(l × W)

Example: English count (Ne), Metric count (Nm), Worsted count ( Nw) etc.

Unit of Length & Weight in Direct Yarn Count System:

Count Calculation In Direct Yarn Count System:

Problem-1:

If a skim of 100 m of filament viscose yarn weights 1.67 gm. Calculate its Denier.

Calculation:

Here,

L = The length of the sample= 100 m

W = The weight of the sample at the official regain in the units of the system= 1.67 gm.

l = The unit of the length of the system

= 9 km

= (9 x 1000)m

= 9000 m

∴ N = (W × l)/L

= (1.67 gm ×9000 m)/(100 m)

= 150.3 den. (Ans)

Problem-2:

If a skim of 350 m of Polyester yarn weights 5 gm . Calculate its Tex.

Calculation:

Here,

L = The length of the sample= 350 m

W = The weight of the sample at the official regain in the units of the system= 5 gm.

l = The unit of the length of the system

= 1 km

= (1 x 1000)m

= 1000 m

∴N = (W × l)/L

=(5 ×1000)/(350)

= 14.28 Tex (Ans)

Unit of Length & Weight in indirect Yarn Count System:

Count Calculation In Indirect Yarn Count System:

Problem-1:

A lea of cotton yarn weights 25 grain. Calculate its count in the cotton or English system.

Calculation:

Here,

L = The length of the cotton sample

= 1 lea

= 120 yds (we know, 1 lea= 120 yds)

W = The weight of the cotton sample at the official regain in the units of the system

= 25 grain

= 25/7000 lb ( we know, 1 lb= 7000 grain)

=0.0036 lb

l = The unit of the length of the system

= 840 yds

w = Unit of weight of the system = 1 lb

∴ N = (L ×w)/(l × W)

= (120 ×1)/(840 ×0.0036)

= 120/3

= 40 Ne (Ans)

Yarn Count Conversion System:

- Conversion from Direct to Direct

- Conversion from Indirect to Indirect

- Conversion from Direct to Indirect

- Conversion from Indirect to Direct

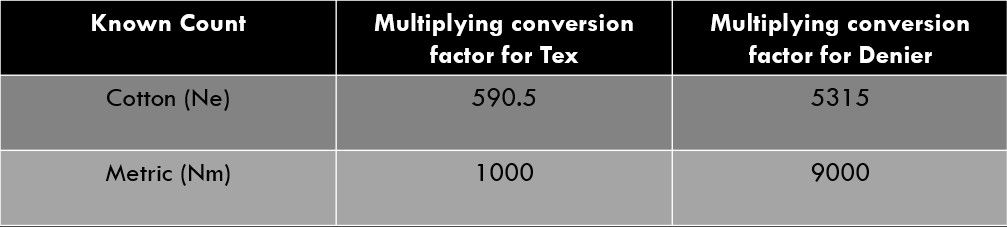

For Unknown Count :

Unknown Count = Multiplying conversion factor × known count

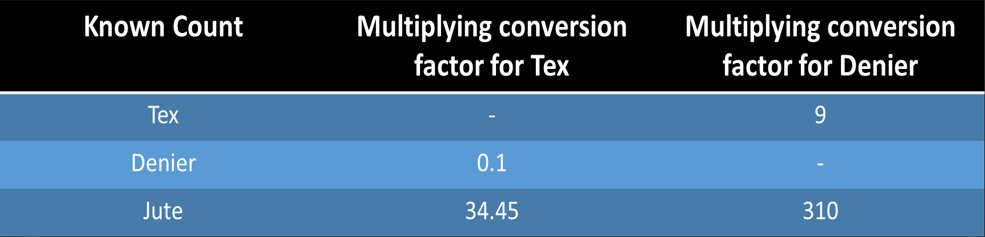

Conversion Chart From Direct to Direct:

Count Calculation From Direct To Direct Yarn Count System:

For,

Denier to Tex,

Denier = 9 × Tex

For,

Tex to Jute,

Tex = 34.45 × Jute

For,

Tex to Denier,

Tex = 0.111 × Denier

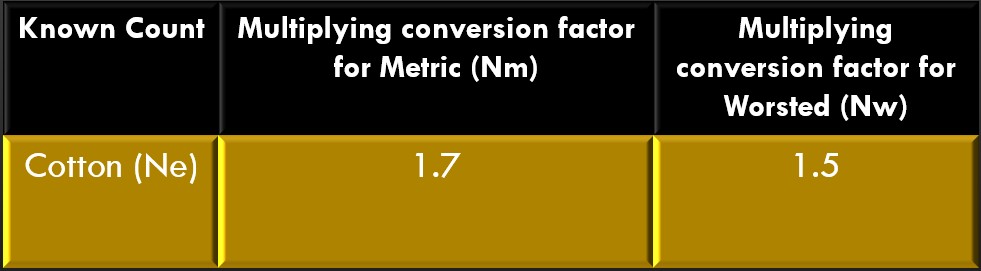

Conversion Chart From Indirect to Indirect:

Count Calculation From Direct To Direct Yarn Count System:

For,

Metric to Cotton or English,

Nm = 1.7 × Ne

For,

Worsted to Cotton or English,

Nw = 1.5 x Ne

Conversion Chart From Direct to Indirect:

Count Calculation From Direct To Indirect and Indirect To Direct System:

For,

Denier to Cotton or English,

Denier = 5315/Ne

For,

Tex to Cotton or English,

Tex = 590.5/Ne

For,

Denier to Metric,

Denier = 9000/Nm

For,

Tex to Metric,

Tex = 1000/Nm

Mathematical Problem Related To Count Conversion:

Problem-1:

Find out the denier count, when Ne = 32 and Tex = 10.

Calculation:

We Know,

For,

Denier to Ne

Denier = 5315/Ne

= 5315/32

= 166.0 (Ans)

For,

Denier to Tex

Denier = 9 x Tex

= 9 x 10

= 90 (Ans)

Problem-2:

Find out the metric count, when Ne = 32 and Tex = 10.

Calculation:

We Know,

For,

Metric to Ne

Nm = 1.7 x Ne

= 1.7 x 32

= 54 (Ans)

For,

Metric to Tex

Nm = 1000/ Tex

= 1000/10

= 100 (Ans)

Relation Between Yarn Diameter & Count:

Let,

Yarn Count = N Tex [ For, Direct System]

∴ Length of N gm of yarn = 1 km

= 1000 m

= (1000 x 100) cm

= 105 cm

∴ Length of 1 gm of yarn = 105/ N cm

Assuming,

The specific volume of the yarn = 1.1 [ By experiment, an apparent specific volume of 1.1 for cotton was found]

∴ Volume of 1 gm of yarn = 1.1 cm3

∴ Length of the 1.1 cm3 of yarn = 105/N cm

We Know,

Volume = Length x Cross-sectional Area

or, 1.1 = 105/N x (πd2)/4 cm

or, d2 = (1.1 ×N ×4)/(105× π)

or, d = 0.375/100 × √N

or, d = k × √N

∴ d ∝ √N [For, Direct System]

For,

Indirect System,

1 inch = 2.54 cm

∴ d = = 0.375/100 × √N × (1/2.54) inch

In Indirect System,

We can assume Ne instead of Tex,

∴ Ne = 590.5/Tex

Or, Tex = 590.5/Ne

∴ d = 0.375/100 × √N × (1/2.54) inch

Or, d = (0.375 ×√590.5 )/(100 ×2.54) × (1/√Ne) inch

or, d = k x 1/(√Ne)

∴ d ∝ 1/√Ne [For Indirect System]

Methods Or Ways Of Yarn Count Measurement:

1. Warp Reel And Analytical Balance Method:

Overview:

This is a standard method used to determine the yarn count, which tells us how fine or coarse the yarn is.

Concept:

Yarn count is a numerical value that describes the thickness of yarn. There are two types of systems:

- Indirect system

- Direct system

Formula:

- Indirect system [N = (L ×w)/(l × W)]

- Direct system [N = (W × l)/L]

- N = The yarn number (Count)

- W = The weight of the sample at the official regain in the units of the system.

- w = The unit of weight of the system

- L = The length of the sample

- l = The unit of length of the system

Tools Required: Warp reel, weighing balance, and a set of standard weights.

Sample Used: Cotton yarn in hank form.

Working Process:

- The warp reel is set up and the yarn is guided from the cone through the reel.

- The reel’s counter measures the yarn length.

- For cotton, the reel has a 1-yard circumference and winds 120 yards. For jute, it’s 2.5 yards circumference with 300 yards needed.

- The cotton reel is motor-driven and stops automatically once the target length is wound; for jute, it’s operated manually.

- The wound yarn is then weighed using a balance.

- This process is repeated 12–16 times. The average is used to calculate the yarn count using the direct count system.

2. Warp Reel And Quadrant Balance Method:

Overview:

Quadrant balance is a direct-reading instrument used to determine the count of short yarn lengths.

Scope:

Can measure counts for yarns up to 40 yards. Also usable for weighing fabric samples.

Principle:

Measures the fineness or thickness of yarn using either:

- Indirect system [N = (L ×w)/(l × W)]

- Direct system [N = (W × l)/L]

Tools Required: Quadrant balance, scale, and blade.

Sample Used: Cotton yarn in roving or sliver form.

Working Steps:

- Measure 4 yards of cotton yarn with a scale.

- Hang the sample on the hook of the quadrant balance.

- Read the count directly from the appropriate scale.

- The balance includes three scales:

- 4 yards for sliver

- 20 yards for roving

- 840 yards for yarn

- Repeat the process 16 times and take the average to find the final count.

3. Warp Reel And Knowles Balance Method:

Structure:

- A beam balance used to find yarn count.

- It has a hexagonal rod with five faces (A to E), each calibrated for different count ranges.

- A screw allows rotation of the rod to bring the required scale into view.

- Matching weights (A to E) go with each scale.

- A sliding rider helps balance the beam.

Procedure:

- Place 120 yards of yarn on the right pan.

- Choose a matching weight (A to E) and place it on the left pan.

- Turn the screw to align the correct scale with the viewer.

- Adjust the rider on the scale until the beam is balanced.

- The rider’s position shows the yarn count.

4. Beesleys Balance Method:

Usage:

Used when only a short piece of cotton yarn is available, either loose or removed from fabric.

Principle:

- A beam with a hook on one end and a pointer on the other.

- The beam is leveled initially with a standard weight on the pointer side.

- Yarn samples are cut using a template and added to the hook until the pointer aligns with the reference line.

- The number of yarn pieces needed for balance gives the count.

Working Steps:

- Choose the right template based on yarn length (short or long cotton).

- Cut yarn pieces using the template and blade.

- Hang them one by one on the hook and count the pieces.

- Repeat the process 10 times and calculate the average for the final count.

Application:

Helps determine the count of yarn taken from a small fabric sample.

Some Important Conversion:

- 1 lb = 7000 grain

- 1 lea = 120 yds.

- 1 yds = 0.914 m

- 1 inch = 2.54 cm

- 1 kg = 2.204 lb

- 1 Hank = 840 yds.

References:

- Principles of Textile Testing by J E Booth.

- Handbook of Textile Testing and Quality Control by E. B. Grover, Elliot Brown Grover, Dame Scott Hamby.

- Physical Testing of Textiles by B.P. Saville.

To learn more on textile testing and laboratory accreditation you can check on the following article:

- Top 3 Effective method of Fiber length measurement

- Testing Of Textiles: Why Is It Important For The Textile And Apparel Industries?

- 10 comprehensive steps in textile fiber sampling method

- 5 EFFECTIVE insights of moisture regain in textile fiber

- Fabric Abrasion Resistance: Martindale Abrasion Testing Process

- Fabric Hand feel evaluation by Fabric Touch Tester (FTT)

- Color Fastness test

- Washing fastness test method: ISO 105 C06

- ISO/IEC 17025 Laboratory Accreditation Process

- ISO/IEC 17025 Laboratory Accreditation Advantages

- KEY STEPS FOR CONDUCTING AN EFFECTIVE QMS INTERNAL AUDIT