What is an Air jet loom?

Air jet looms, operating at remarkable speeds of up to 2000 picks per minute(PPM). Air jet emerge as a prime selection for swiftly yielding significant fabric output. This technology is particularly useful in efficiently producing large fabric volumes. Notably, the textile industry frequently employs air jet looms to weave a variety of fabrics.

Air jet loom is the fastest traditional method of weaving in modern manufacturing. However, the amount of compressed air essential to run these looms and the complexity of the air jet position make them more costly than other looms. To compare Air jet loom with other looms, one should go through the following article- Revelation and Classification of weaving loom.

History behind Air jet loom:

The commencement of the air-jet loom took place in Czechoslovakia during the 20th century. Following its invention the air-jet loom underwent refinements by companies from Switzerland, the Netherlands, and Japan.

Working Principle of Air Jet Weaving Machine:

The principle of air jet weaving involves the utilization of propelling. The air jet loom operates by pushing the weft yarn through the warp yarn using compressed air. Employing a high-pressure air jet, it inserts the weft yarn into the warp shed and swiftly carries it across the loom, thereby completing the weaving process.

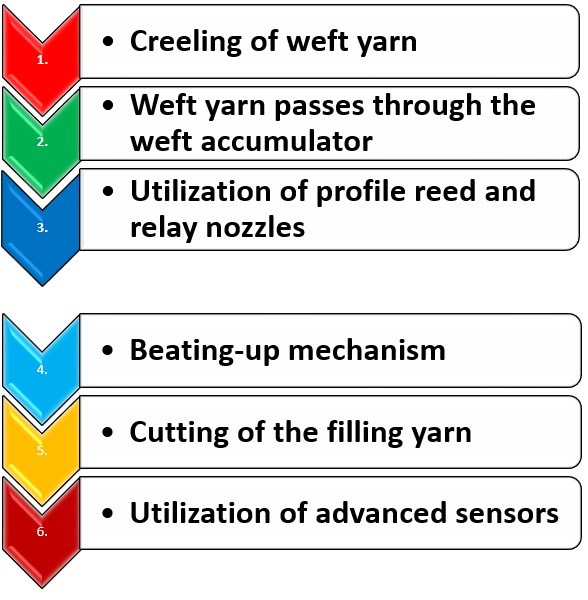

Flow diagram for basic principle operations of air jet weaving machine

- The creel holds the weft yarn package. Depending on the number of weft colors, the weavers determine the quantity of weft packages.

Creel of weft yarn package - Subsequently, the weft yarn passes through the weft accumulator, a component that guarantees a consistent weft supply with uniform tension throughout the weft insertion process.

-

-

- First, releasing the weft brake on the weft accumulator.

- Next, activate the air supply to the main nozzle.

- As the main nozzle’s compressed air stream comes into play, it effectively pulls the weft yarn into the shed.

-

Weft Accumulator

-

-

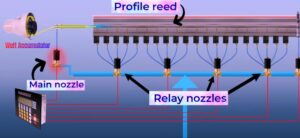

- Air jet weaving machine involves employing a system with multiple nozzles and a profiled reed. With the assistance of a profiled reed and multiple relay nozzles, the weft yarn traverses through a stationary weft passage.

-

-

- To complete the task of inserting the weft yarn from one selvage to the other, a single main nozzle is insufficient. Therefore, a number of relay nozzles activate sequentially, each triggering promptly after the preceding one.

- As the weft concludes its trajectory, the weft brake promptly initiates its operation. Subsequently, the air stretch nozzle sucks the tail of the weft yarn.

Weft Insertion Mechanism

-

-

- Once the weft yarn finds its place within the shed, the beating-up mechanism engages, firmly pressing the weft yarn into position, and generating a tightly woven fabric.

- While the reed initiates its movement away from the fabric’s fell, the filling cutter cuts the filling yarn. This sequence of actions repeats in an ongoing manner.

- Equipped with cutting-edge sensors and cameras, contemporary air jet looms actively monitor the weaving process. These components make real-time adjustments to yarn tension and positioning, ensuring both the quality and uniformity of the fabric.

The Speed and Challenges of High-Speed Air-Jet Looms for Weaving:

The speed of air-jet loom achieves remarkable swiftness in its operations. With a weft insertion rate ranging from 1500-2000 m/min, or even exceeding 2500 m/min, its pace is substantial. When the weft insertion rate reaches 2000 m/min, the weft attains a velocity of about 120 km/h, equivalent to highway car speeds. The transition of the weft in and out takes an incredibly brief period of only around 0.05 seconds, accompanied by an initial filling-in speed ranging between 35 ~ 40 m/s.

However, challenges emerge during this high-speed process. Upon completion of filling insertion, the stopper of the filling feeder immediately stops feeding. Nonetheless, the airflow from the main and auxiliary nozzles doesn’t halt instantly. This design feature leads to an abrupt impact load on the filling yarn as it reaches the opposite side of the fabric. This occurrence triggers the maximum tension during filling insertion, often termed the “tension peak.”

Consequently, if the weft’s breaking strength significantly lags behind the peak tension during insertion, the risk of breakage and subsequent stoppage arises. Therefore, accurate weaving technology configuration and the selection of high-quality weft material emerge as crucial factors in navigating these challenges.

Renowned for its elevated weaving speed and adaptability, the air jet loom enables the creation of a diverse array of fabrics exhibiting various colors, patterns, and textures.

6 thoughts on ““Air Jet Looms: Revolutionizing Textile Production with Speed and Precision””

There is a lot to learn and understand by reading this article. Thank you sir for such a nice article explaining it properly.

Thanks Shihab.

Nice Explain Sir🥰

Thanks Abed.

Dear Sir,

Love your textile article vlogs and YouTube video tutorials Your article will help reach relevant audience interested in knitting and modern weaving technology.

Thanks Mr Zia for your kind words.