What is Spandex?

Spandex is a synthetic fiber containing a maximum of about 85% segmented polyurethane and known for its high elasticity with an elongation capacity of approximately 600%. Lycra is a brand name rather than a specific type of fiber for Spandex or elastane yarn. The DuPont Company of Virginia pioneered the development of spandex or elastane fibers. This development took place between 1958 and 1959.

Different kinds of spandex yarn:

- Bare yarn.

- Covered yarn.

- Core spun yarn.

- Blend spun yarn.

Brand labels of manufacturers producing spandex:

- ROCIA

- Linel

- Elaspan

- ESPA

- Texlon

How Spandex is made?

In a laboratory environment, researchers synthesize all elements of spandex. Although the chemicals utilized to create spandex may initially come from organic origins, they undergo substantial formulation and alteration, resulting in minimal resemblance to their original forms.

Manufacturers can produce spandex using four different approaches, yet the majority of these methods have largely been abandoned. While some producers still utilize reaction spinning, solution wet spinning, or melt extrusion to manufacture elastane products, solution dry spinning takes the lead, accounting for over 95% of the world’s spandex production.

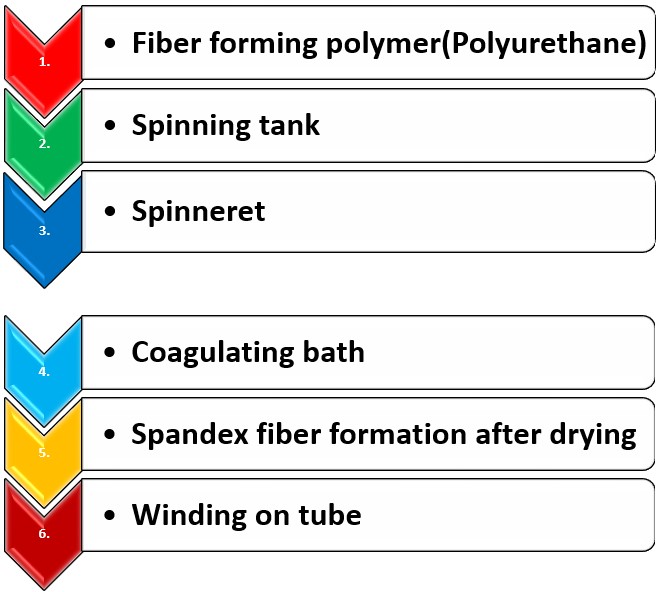

Flow diagram of the manufacturing process of Spandex:

In producing Spandex, manufacturers combine macro glycol and a diisocyanate monomer to form the prepolymer, a fundamental constituent. They then initiate the chemical process for creating the prepolymer by subjecting the solution to carefully controlled heat and pressure conditions. Maintaining a 1:2 volume ratio between these components is crucial, as an imbalanced ratio hampers prepolymer formation.

Following this, the prepolymer undergoes a chain extrusion reaction with diamine acid, resulting in a highly viscous substance. To manage its thickness, manufacturers introduce a solvent. They feed the thinned solution into a fiber production cell, which is a cylindrical device featuring a specialized spinneret. As the solution passes through the spinneret, it transforms into fibers. Before solidification, these fibers are exposed to a heated nitrogen and solvent gas mix.

Once solidified, manufacturers extrude the filaments from the spinning cell and shape them into bundles using compressed air, which also adds a twisting effect to meet the requirements of different textile uses. This process yields a diverse range of yarn sizes suitable for different consumer textile needs.

Properties of Spandex:

Properties of spandex include-

- Physical properties

- Chemical properties

- Thermal properties

- Electrical properties

Physical Properties:

- Elasticity: Spandex is highly elastic, providing exceptional stretch and recovery, making it suitable for fitting garments. Spandex has the ability to stretch beyond 500% of its original size without breaking and can revert to its initial shape once the tension is released.

- Tenacity: Approximately 7 gm/denier or higher.

- Moisture Regain (MR%): Moisture regain of Spandex is 0.6%. While spandex itself is not particularly hydrophilic (able to absorb water), when blended with other fibers, the resulting fabric can be designed to wick moisture away from the skin, making it suitable for active-wear. It is suitable for swimwear and other water-related applications.

- Specific gravity: Approximately 1.21 to 1.35.

- Dimensional stability: Water doesn’t cause shrinkage, but temperature changes can lead to contraction.

- Resistance to abrasion: Very good.

Chemical Properties:

- Reaction with acid: Spandex is resistant to acid.

- Reaction with alkali: Damage from hot alkali is possible.

- Reaction with bleaches: It maintains resistance at temperatures below 150°F. Researchers are trying to improve the condition.

- Reaction with organic solvents: Resistant to all forms of organic solvents.

- Capability for dyeing: Suitable for acid, disperse and chrome dyes.

- Washing and Cleaning: Spandex is often resistant to damage from detergents and cleaning agents used in laundering, contributing to its longevity.

- Compatibility: When blending with other fibers, the chemical compatibility between spandex and the other fibers is important to ensure the overall stability of the fabric.

Thermal Properties:

- Thermal conductivity: Poor

- Heat Sensitivity: While spandex can withstand a range of temperatures, excessive heat can lead to deformation or damage, affecting its elasticity.

- Action with sunlight: Able to withstand light.

- UV Stability: Depending on its formulation, spandex can have varying degrees of resistance to ultraviolet (UV) light, protecting it from degradation due to sun exposure.

- Action with flame: Spandex burns rapidly.

Electrical Properties:

- Electrical conductivity: Spandex has a low conductive nature.

Uses of different Spandex Yarn:

- Bare yarn: In terms of knit fabric production, it is particularly well-suited for hosiery and socks manufacturing.

- Covered yarn: Suitable for foundation garments, swimwear, and support hose manufacturing.

- Core spun yarn: In knit fabrics, specially for sportswear manufacturing

- Blend spun yarn: For fabric manufacturing, that is ideal for calendaring.

Application Areas of Spandex:

1. Active-wear:

Spandex is a crucial component in many sports and active-wear such as leggings, tights, sports bras, and athletic shorts. Its elasticity helps the garments adhere to the body, allowing for more flexibility of movement.

2. Swimwear:

Spandex is often incorporated in swimsuits to provide a snug fit and shape retention both in and out of water.

3. Compression Garments:

These garments stimulate blood flow and provide support for muscles whether worn for medicinal or athletic purposes. This includes clothing such as stockings, socks, and compression sleeves.

4. Performance Costumes:

Dance-wear, figure skating dresses, and some theatrical costumes use spandex for its flexibility, allowing performers a wide range of motion.

5. Casual Wear:

Some casual wear, like jeans, have a little flexibility since they are manufactured with a cotton and spandex mixture, which can improve comfort and fit.

6. Fitted Sheets:

Some bed sheets have a little amount of spandex to help them fit tightly around mattresses and stay there.

7. Medical and Orthopedic Supports:

To allow for movement while providing medical and orthopedic support, spandex is sometimes used in items like wrist guards, knee braces, and other joint supports. Some bandages and wraps used for supporting or preventing injuries may contain spandex.

8. Diapers:

To guarantee a secure fit around the baby, some contemporary cloth diapers have a spandex component in their outer shells or in the leg gussets.

9. Shape-wear:

Spandex is frequently seen in clothing intended to slim, smooth, or shape the body. This includes clothing such as bodysuits, pantyhose with a control top, and waist cinchers.

10. Cosplay & Costuming:

Due to its form-fitting attributes, individuals who create and design their own costumes for events, conventions often use spandex. For example- Spider-man costume, Batman costume, Superman costume, Black panther costume etc.

11. Sock Tops:

To help socks stay up and not slouch down.

Pros and Cons of Fabrics Associated With Spandex:

- Fabrics containing spandex experience the highest process losses.

- Before dyeing, fabrics containing spandex should undergo heat setting. If not properly set, compromises color retention and leads to the formation of crease marks.

- Fabrics containing spandex express the spandex amount as a percentage, such as 5% Spandex, 10% Spandex, 15% Spandex, and so on.

- When dyeing Lycra fabric, manufacturers encounter a process loss of 8–10% for dark colors and 10–14% for lighter shades.

- While knitting, the Spandex/Lycra machine utilizes three feeding methods, for example:

A) Full Feeder Lycra

B) Half Feeder Lycra

C) Quarter Feeder Lycra.

Determination of Set% for Spandex:

The percentage of set defines the natural elasticity of spandex fiber. Imagine a fiber AB elongated to position C by pulling, and it reaches point D. When the pull is released, we notice that the fiber doesn’t completely return to position B, showing a recovery of less than 100%. Hence

Factors influence the set% of elastomeric fiber:

Factors:

- Chemical composition.

- Cross link density: (density , set ↓ ).

- Testing condition:

- The amount of stretch.

- Duration of stretch.

- Time lapse between and measurement of the next test.

7 thoughts on “Spandex Fiber: An Elastic Marvel”

The recovery and life time of spandex is not good. also it is not recyclable. Now duppont innovated a new fiber(Sorona). which recovery and life time is good. Also recyclable.

Thanks for the update Sonjoy das.

Keep up the good work! Sir.

Thanks Abed.

Dear Sir,

Assalamu alaikum.I read all article which you make by lot of research, All are essential helpful for your textile related activities.May Allah bless you for continuing.

Best wishes

Md Ziaur Rahman

Thanks MD. Ziaur Rahman.Hope that I am able to deliver you the right content as always. Keep learning and sharing.

Regards

Musfiqur Rahman

Keep up the good work! Sir.