Roll-to-roll sublimation printing:

Technology Behind Sublimation Printing Process:

How Does Sublimation Printing Works?

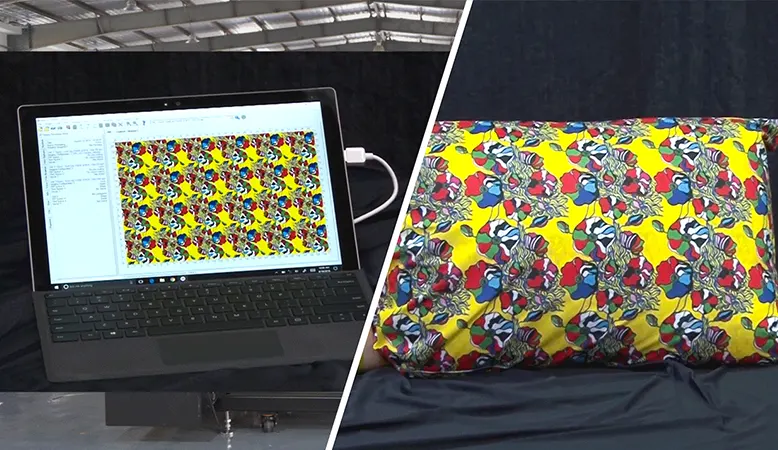

Step 1: Ready Your Design:

Step 2: Printing:

Step 3: Fusing or Heat Transfer:

Steps in Roll-to-roll sublimation printing process:

Step 1: create sublimation designs:

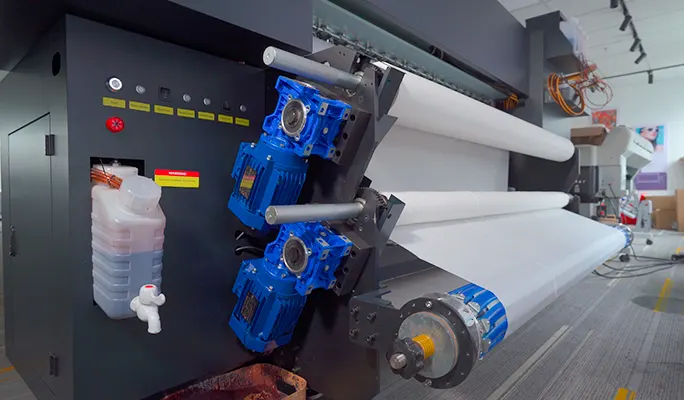

Step 2: Printing Setup:

Step 3: Print Design:

Step 4: Roll-To-Roll heat transfer:

Advantages of Roll-to-roll sublimation printing:

- Stunning designs.

- High definition prints.

- Colorfast.

- Durable.

- Resistant to fading or cracking.

- Jumbo roll up to 3000 meter.

- Mass production.

Applications of Roll-to-roll sublimation printing:

- Fashion.

- Sportswear.

- Home Textiles.

- Indoor soft signage.

References:

4 thoughts on “Roll-to-roll sublimation printing process”

🥰

Dear Sir, It’s very much helpfull for textile industry. Thanks for your guidance.

Best regards

Md Ziaur Rahman.

Thanks for the compliments dear Mr. Zia.

My sublimated fabric smudges or loses color after ironing during stitching. Please assist